you can rely on

- Long-term expertise in chemistry, ceramics, glass and powder metallurgy

- Quality control of every batch – both raw materials and finished products

- Optimal synergy effects

- Worldwide network and competence

- Personal consultation

Founded in 1894, Zschimmer & Schwarz is a family business that supplies a wide range of industries with chemical auxiliaries and specialities. With more than 1,500 employees, 27 companies in 16 countries, 7 highly specialised business divisions and customers across all continents, Zschimmer & Schwarz stands for “chemistry tailor-made”.

Use the sidebar on the right

to get in touch

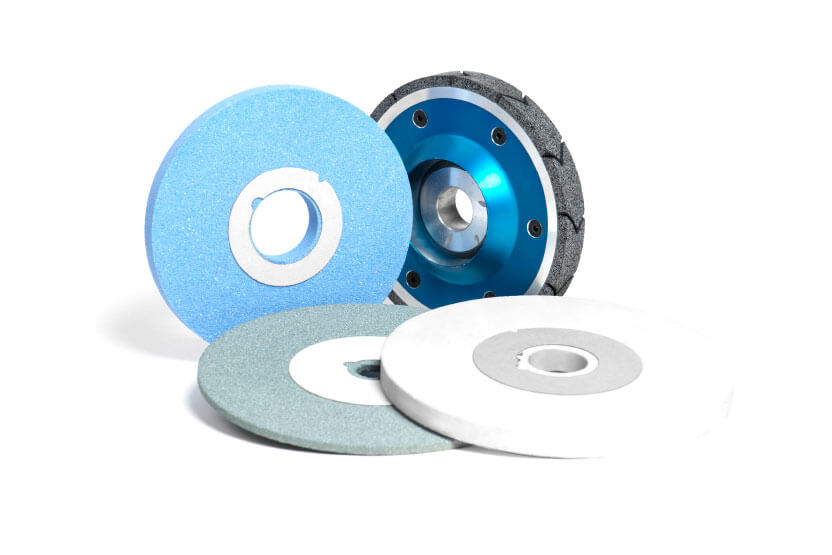

The Zschimmer & Schwarz Ceramic Auxiliaries Division offers a wide range of customised products and services for the ceramics industry. In addition to process additives for classic ceramics segments such as tiles, tableware, sanitary ware and refractories, our extensive portfolio also includes technical ceramics, silicate ceramics and abrasives as well as glass and powder metallurgy.

TRUCOLOR 219 BLUE

TRUCOLOR 430 CYAN

TRUCOLOR 210 RED BROWN

TRUCOLOR 211 YELLOW

TRUCOLOR 217 BLACK

TRUCOLOR 393 BLACK

TRUCOLOR 209 PINK

TRUCOLOR 206 BEIGE

TRUCOLOR 236 ORANGE

TRUCOLOR 281 REDORANGE

TRUCOLOR 261 RED BROWN

TRUCOLOR 285 GREEN

TRUCOLOR 242 WHITE

TRUCOLOR 408 GOLDENYELLOW

TRUCOLOR EF 245

TRUCOLOR EF 389 MATT TRANSPARENT

TRUCOLOR 398 LUSTER

TRUCOLOR 402 GLOSSY

TRUCOLOR EF 432 TEXTURE

TRUCOLOR EF 438 TEXTURE MATT

TRUCOLOR EF 401 METALLIC

Dispersants

| DOLAPIX PC 67 | Polycarboxylic acid, sodium salt |

| DOLAPIX SPC 7 | Preparation of silicate-polycarbonate |

| GIESSFIX 162 | Sodium disilicate |

| GIESSFIX ZS | Alkali silicate |

Filtration agents

| DOLACAST 58 | Preparation of polyamines and synthetic polymers |

| PRODUKT KX 1664 | Preparation of polyamines and synthetic polymers |

| PRODUKT KX 1666 | Preparation of polyamines and synthetic polymers |

Temporary binders

| OPTAPIX AC 112 | Aqueous polymer dispersion, temporary binder for slip casting |

| OPTAPIX PS 17 | Modified polysaccharides in aqueous solution, temporary binder for sticking mud |

| PRODUKT KB 1279 | Aqueous polymer dispersion |

Cleaning agents

| GLYDOL 1161 | Polycarboxylate with anionic surfactants |

| GLYDOL 1190 | Polycarboxylate with anionic surfactants |

| GLYDOL 1196 | Polycarboxylate with anionic surfactants, latest development |

Plaster additives

| SILUBIT G 80 | Melamine preparation |

Release agent

| TRENNEMULSION W-165 | Emulsion of surface-active agents and mineral oils |

Fixative for decals

| DOLAFIX 88 | Polymers in aqueous solution; in combination with PRODUKT KD 8042, drying time can be adjusted |

| Product | Viscosity | Drying time | Yield point |

|---|---|---|---|

| Rheological additives | |||

| PEPTAPON 44 | medium | basic | medium |

| PEPTAPON 52 | basic | medium | medium |

| PEPTAPON 71 S | basic | long | basic |

| PEPTAPON 88 | basic | basic | medium |

| PEPTAPON 99 | medium | medium | medium |

| PEPTAPON 205 | high | basic | high |

| PEPTAPON 1615 EF | basic | long | basic |

| Temporary binders (CMC) | |||

| OPTAPIX C 12 G | basic | basic | |

| OPTAPIX C 50 G | medium | medium | |

| OPTAPIX C 1000 G | high | long |

Biocides

| PREVENTOL® P 301 | Aqueous formulation of bronopol and isothiazolinone |

Dispersants

| GIESSFIX G 3 | Sodium polyphosphate |

| DOLAPIX G 10 | Polycarboxylic acid, sodium salt |

Suspension aids

| STELLMITTEL 279 | Polyammonium derivates |

| STELLMITTEL ZS | Mixture of electrolytes |

| Product | Viscosity approx. 15% in mPa*s | Pressing aid | Antifoam | Form of delivery |

|---|---|---|---|---|

| Binders | ||||

| OPTAPIX PA 51 | 5500 | Low content | High content | Powder |

| OPTAPIX PA 52 | 750 | High content | High content | Powder |

| OPTAPIX PA 53 | 850 | High content | High content | Powder |

| OPTAPIX PA 54 | 1100 | High content | High content | Powder |

| OPTAPIX PA 55 | 400 | High content | Powder | |

| OPTAPIX PAF 2 | 4000 | High content | High content | Liquid |

| OPTAPIX PAF 46 | 1000 | High content | Liquid |

Pressing agents

| ZUSOPLAST WE 50 | Wax dispersion |

| ZUSOPLAST 9002 | Polyoxyethylene preparation |

Dispersants

| DOLAPIX PC 67 | Polycarboxylic acid, sodium salt |

| DOLAPIX PC 187 | Polycarboxylic acid, sodium salt |

| DOLAPIX PC 207 | Polycarboxylic acid, sodium salt |

| PRODUKT KV 5202 | Polycarboxylic acid, sodium salt |

| DOLAPIX SPC 7 | Silicate-polycarbonate preparation |

| DOLAPIX PC 29 | Phosphonate preparation |

| GIESSFIX PT 88 | Phosphonate preparation |

| DOLAFLUX SP 11 | Huminate-silicate preparation |

| OPTAPIX G | Binders for glazes |

| CONTRASPUM | Antifoam agents |

| PREVENTOL | Biocides |

| DOLACAST | Filtration agents |

| GLYDOL | Cleaning agents |

| TRENNEMULSION | Release agents |

Flocculants

| KERAFLOC AL FLUESSIG | Flocculant for silica sole |

| KERAFLOC AL PULVER | Flocculant for silica sole |

Waterglass hardener

| LITHOPIX P 26 | Controlled, irreversible precipitation of silicic acid |

Wetting agents

| GLYDOL 1195 | Blast furnace taphole bodies, carbonic ramming and extrusion bodies |

| GLYDOL N 1003 | Wetting agent and plasticiser for clay-containing bodies, ramming mixes |

| GLYDOL N 1055 | Wetting agent and plasticiser for clay-containing bodies, castables |

| GLYDOL N 2002 | Blast furnace taphole bodies, carbonic ramming and extrusion bodies |

Setting accelerators / retardants

| LITHOPIX LCA | Cement-bonded bodies / retardant |

| SILUBIT BL 05 | Cement-bonded bodies / accelerator |

| SILUBIT P 67 | Cement-bonded bodies |

Chemical binders

| LITHOPIX AS 21 | Cement-free gunning mixes |

| LITHOPIX AS 36 | Cement-free gunning mixes |

| LITHOPIX AS 85 | Neutral, cement-free vibration bodies |

| LITHOPIX P 1 | Bodies and bricks |

| LITHOPIX P 2 | Storable, workable bodies |

| LITHOPIX P 4 | Acidic ramming and gunning mixes |

| LITHOPIX P 5 | Basic vibration and casting bodies |

| LITHOPIX P 6 | Basic brick, ramming and gunning mixes |

| LITHOPIX P 8 | Basic brick, ramming and gunning mixes |

| LITHOPIX P 9 | Neutral brick, ramming and gunning mixes |

| LITHOPIX P 15 | Neutral bodies and mortars |

| LITHOPIX P 33 | Neutral brick, ramming and gunning mixes |

| LITHOPIX P 40 | Storable, workable bodies |

| LITHOPIX P 56 | Gunning mixes for hot repairing |

| LITHOPIX P 91 | Bodies and mortars from neutral raw materials |

| LITHOPIX P 92 | Ready-to-use mortars |

| LITHOPIX S 2 | Mortars, gunning mixes and core sands |

| LITHOPIX S 3 | Mortars, gunning mixes and core sands |

| LITHOPIX S 12 | Tundish gunning mixes |

| LITHOPIX S 66 | Mortars, gunning mixes and core sands |

| LITHOPIX ST 5 | Insulating tundish gunning mixes |

| LITHOSOL 1530 | Ceramic fibres, castables |

| LITHOSOL 1540 | Ceramic fibres, castables |

| SILUBIT FB 10 | Binder and thixotropic agent for vibration bodies |

| SILUBIT FB 29 | Binder and thixotropic agent for vibration bodies |

| SILUBIT FB 70 | Binder and thixotropic agent for vibration bodies |

| SILUBIT H 19 | Low-cement gunning mixes |

Plasticisers / Stabilisers

| ZUSOPLAST C 39 | Pressing, ramming and extrusion bodies |

| ZUSOPLAST PS 1 M | Pressing, ramming and extrusion bodies |

| PEPTAPON 5 | Stabiliser for pressing, ramming and extrusion bodies |

| PEPTAPON 9 | Stabiliser for pressing, ramming and extrusion bodies |

| PEPTAPON 71 S | Stabiliser for pressing, ramming and extrusion bodies |

Porosity-inducing agents

| CELLOTIN PP 6 | Dewatering aid |

| CELLOTIN ZZ 8/1 | Insulating tundish gunning mixes, also used as a separation inhibitor |

| GLYDOL N 1058 | Foam ceramics |

| PORLAT K 85-90 | Targeted adjustment of pore size, pore volume and pore distribution |

Pressing agents

| ZUSOPLAST 126/3 | Dry pressing bodies and extrusion bodies |

| ZUSOPLAST 5012 | Basic dry pressing bodies, also water-free |

| ZUSOPLAST O 59 | Dry pressing bodies and extrusion bodies |

| ZUSOPLAST E 1 | Basic dry pressing bodies, also water-free |

Dust-binding agents

| ZUSOPLAST S 13 SPEZIAL | Gunning mixes |

Temporary binders

| LITHOPIX LCA | Increase of green and dry strength |

| OPTAPIX AC 15 | Increase of green and dry strength |

| OPTAPIX AC 51 | Increase of green and dry strength |

| OPTAPIX PAC 60 | Mortars |

| OPTAPIX PAF 35 | Increase of green and dry strength |

Release agents

| TRENNEMULSION W 165 | Release agent for refractory parts |

| ZUSOPLAST O 59 | Clay-containing pressing, squeeze and extrusion bodies |

Deflocculants / dispersants

| DOLAPIX CE 64 | Oxidic bodies, also cement-bonded |

| DOLAPIX FF 1 | Oxidic bodies, also cement-bonded |

| DOLAPIX FF 7 SPEZIAL | Oxidic bodies, also cement-bonded |

| DOLAPIX FF 26 | Free of microsilica, also cement-bonded |

| DOLAPIX FF 44 | Contains microsilica, also cement-bonded |

| DOLAPIX FF 54 | Contains microsilica, also cement-bonded |

| GIESSFIX PT 88 | Oxidic bodies, also cement-bonded |

Others

| ZUSOPLAST G 112 | Anti-freezing solution for cement, silica sole and waterglass-containing bodies |

Wetting agents

| GLYDOL N 2002 | Preparation based on Dodecylbenzenesulfonic acid, monoethanolamine salt |

| GLYDOL N 1055 | Polyarylsulfonate |

| GLYDOL 1144 | Preparation of polymers in solvents |

Pressing agents

| ZUSOPLAST WE 8 | Non-ionic wax dispersion |

| ZUSOPLAST WE 50 | Non-ionic wax dispersion |

| ZUSOPLAST 52 | Non-ionic wax dispersion |

Lubricants

| ZUSOPLAST 91/11 | Preparation of surfactants |

| ZUSOPLAST 126/3 | Fatty acid preparation with non-ionic emulsifier |

| ZUSOPLAST O 59 | Low-hazardous hydrocarbons |

Temporary binding agents

| OPTAPIX PS 94 | Polysaccharide preparation |

| OPTAPIX PS 224 | Polysaccharide preparation |

| OPTAPIX PS 202 | Polysaccharide preparation |

| OPTAPIX AC 112 | Aqueous polymer dispersion |

| OPTAPIX AC 15 | Polycarbonic acid preparation |

| OPTAPIX AC 51 | Aqueous polymer dispersion |

Porosity-inducing agents

| PORLAT K 85 | Polymethyl methacrylates |

| PORLAT K 86 | Polymethyl methacrylates |

| PORLAT K 87 | Polymethyl methacrylates |

| PORLAT K 88 | Polymethyl methacrylates |

| PORLAT K 89 | Polymethyl methacrylates |

| PORLAT K 90 | Polymethyl methacrylates |

| Product | Viscosity | Drying time | Yield point |

|---|---|---|---|

| Rheological additives | |||

| PEPTAPON 71 S | basic | long | basic |

| PEPTAPON 88 | basic | basic | medium |

| PEPTAPON 205 | medium | basic | high |

| Temporary binders | |||

| OPTAPIX C 50 G | medium | medium | |

| OPTAPIX C 1000 G | high | long | |

| OPTAPIX G 35 | neutral | neutral |

Wetting agents

| PRODUKT KG 9046 | Improvement of the overglazing properties of difficult surfaces |

Granulate application

| DOLAFIX 1032 | Glaze fixative to fix granules on dry and wet surfaces |

| GRANICER 6002 | Ideal for dry application of grit |

| GRANICER 7068 | Ideal for low quantity of grit per square metre |

| GRANICER 7070 | Ideal for high quantity of grit per square metre |

| Product | Mixing water | Plasticity | Dry breaking strength (MOR) | Moisture in quarry clay |

|---|---|---|---|---|

| CLAYFORM B 2 | x | x | ||

| CLAYFORM B 62 | x | x | ||

| CLAYFORM V 7 | x | |||

| CLAYFORM V 13 | x | |||

| CLAYFORM V 65 | x | |||

| CLAYFORM V 67 | x | |||

| CLAYFORM P 2 | x | x | ||

| CLAYFORM P 17 | x | x | ||

| CLAYFORM P 51 | x | x | ||

| CLAYFORM GF PS | x |

| Shaping process

| ||||

| Product | Chemical basis | Pressing | Extrusion | Casting |

|---|---|---|---|---|

| Temporary binders | ||||

| OPTAPIX AC | Acrylate | Standard | Standard | Standard |

| OPTAPIX PAC | Acetate | Standard | Standard | Standard |

| OPTAPIX PAF | Polyvinyl alcohol | Standard | Standard | |

| Pressing agents | ||||

| ZUSOPLAST E | Oil emulsifiable | Standard | Standard | |

| ZUSOPLAST G | Polyoxyethylene | Standard | Standard | |

| ZUSOPLAST O | Hydrocarbons | Special application | Standard | |

| ZUSOPLAST WE | Wax emulsion | Standard | Standard | |

| Plasticisers | ||||

| ZUSOPLAST C | Cellulose derivative | Standard | ||

| ZUSOPLAST PS | Polysaccharide | Special application | Standard | |

| Dispersants | ||||

| DOLAPIX A | Amino alcohol | Standard | Standard | |

| DOLAPIX CA | Carboxylic acid | Standard | Standard | |

| DOLAPIX ET | Carboxylic acid ester | Standard | Standard | |

| DOLAPIX PC | Synthetic polyelectrolyte | Standard | Standard | |

Please do not hesitate to contact us – we are happy to advice you on your specific application.

Oxidation inhibitors

| METAMAX I-15 | Minimises oxidation in water |

Pressing – temporary binders

| METAMAX B-508 | Polymer, inhibitor |

| METAMAX B-129 | Polymer, inhibitor |

| METAMAX B-4 | Wax dispersion |

| METAMAX B-26 | Polymer, high edge stability |

| METAMAX B-17 | Wax dispersion for China & USA |

Pressing – other additives

| METAMAX S-10 | Wetting agent |

| METAMAX S-20 | Suspension stabiliser |

| CONTRASPUM K 1012 | Antifoam agent |

| CONTRASPUM K 1045 | Antifoam agent |

Extrusion – temporary binders

| PRODUKT KM 4128 | Humectant, binding agent |

Extrusion – plasticisers

| METACEL 7026 | Cellulose ether |

| METACEL 16 | Cellulose ether |

| METACEL 35 | Cellulose ether, with a low fibre content |

Extrusion – pressing agents and lubricants

| METAMAX L-09 | Pressing agent, emulsifiable |

| METAMAX L-10 | Pressing agent and lubricant |

| METAMAX L-201 | Pressing agent, emulsifiable |

Pressing

| METAMAX G-26 | Temporary binder |

| METAMAX L-09 | Pressing agent, emulsifiable |

| METAMAX L-10 | Pressing agent and lubricant |

| METAMAX L-201 | Pressing agent, emulsifiable |

Release agents for sinter carriers

| METAGRAF C | Graphite dispersion |

| METAGRAF A-22 | Al₂O₃-dispersion |

| METAGRAF Z | ZrO₂-dispersion |

| METAGRAF Y | Y₂O₃-dispersion |

Looking for more details about

our ceramic auxiliaries?

Ask us!

Zschimmer & Schwarz develops tailor-made solutions for customers across the globe. Our competencies in the international application technology laboratories in the fields of chemistry and ceramics ensure consistently high product quality. In addition to innovation, research, reliability and quality, we are also highly focused on sustainability. As part of this, Zschimmer & Schwarz continuously works on optimising all production steps and conserving precious resources: with material efficiency, minimisation of process water requirements, energy efficiency and the use of renewable raw materials, we are shaping the future.

Zschimmer & Schwarz offers a comprehensive measurement service covering all areas of developing innovative process additives. The wide variety of ceramic preparation processes is also reflected in the modern laboratory equipment. This enables us to offer special solutions for all customer-specific challenges.

All substantial ceramic shaping processes can be simulated in our laboratories. In this way, we ensure optimal transfer to our customers' production processes.

With the help of our comprehensive laboratory equipment for research and analysis of our process additives and their mode of action, we are in the position to provide targeted and customer-specific product recommendations. Together with our customers, we develop novel, innovative and sustainable solutions.

Looking for more detailed information?

Ask us!

Use the sidebar on the right

to get in touch